Description

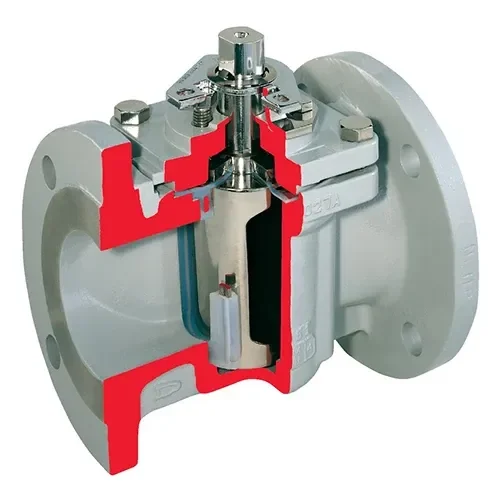

A ball valve is a type of quarter-turn valve that uses a ball-shaped disk to control the flow of fluids or gases through a pipeline. The ball valve is made up of a hollowed-out, floating ball with a hole through its center. The valve is opened or closed by turning the ball 90 degrees, which aligns or blocks the hole with the flow of the pipeline.

Ball valves can be used in a variety of applications, including in water supply systems, natural gas pipelines, and chemical processing plants. They are often preferred over other types of valves because of their ease of operation, durability, and ability to provide tight shut-off and control over the flow of fluids.

Ball valves come in a range of sizes, materials, and designs to suit different applications. Some ball valves are made of metal, such as brass, stainless steel, or cast iron, while others are made of plastic or other materials. Ball valves can also be designed with different end connections, including threaded, flanged, or welded connections, to allow for easy installation in different types of pipelines.

One of the main advantages of ball valves is their fast and easy operation, which makes them ideal for applications where rapid control of the flow is required. They also require minimal maintenance and are less likely to leak than other types of valves. However, they may not be suitable for applications where fine control over the flow of fluids is required, as they have a limited range of opening positions.