ABOUT-

The fertilizer sector in India has witnessed significant expansion in recent years due to the country’s substantial and growing population and the surging demand for food. The Indian government has been supportive of the industry, providing subsidies and tax benefits to manufacturers, and investing in research and development and infrastructure.

India has become a leading producer of fertilizers, particularly urea, in recent years, and exports a considerable portion of its output to other nations. Additionally, the country is also increasing its production of more complex fertilizers, such as NPK, to cater to the evolving requirements of Indian farmers.

However, the fertilizer industry in India still confronts several challenges, including low agricultural efficiency, uneven distribution of fertilizers, and insufficient infrastructure, particularly in rural areas. Moreover, the industry has been impacted by variations in the prices of raw materials and energy, which can significantly affect the production cost.

In conclusion, the growth of the fertilizer industry in India has been positive but still has room for improvement, particularly in terms of increasing access to fertilizers for farmers, enhancing fertilizer efficiency, and minimizing the environmental impact of fertilizer production and utilization.

ASSOCIATION-

|

NAME |

URL |

|

International Fertilizer Association | |

|

The Fertilizer Association of India |

DESCRIPTION-

A fertilizer is any natural or synthetic material that is applied to soil or plant tissues to improve their growth and productiveness. The fertilizer industry plays a critical role in the worldwide agriculture industry by creating and distributing various fundamental nutrients that aid in the growth and prosperity of crops. The three main types of fertilizers are nitrogen, phosphorus, and potassium, also known as NPK fertilizers, which serve as the key macronutrients for plant survival.

There are three primary categories of fertilizers:

- Nitrogen-Based Fertilizers: Nitrogen plays a crucial role in plant growth and is responsible for the green coloration of leaves and stems. Nitrogen-based fertilizers come in a variety of forms, including urea, ammonium nitrate, and calcium nitrate. These fertilizers are utilized to boost crop yields and improve the quality of crops.

- Phosphorus-Based Fertilizers: Phosphorus is an indispensable nutrient for plant growth and contributes to photosynthesis, energy storage, and cell division. Phosphorus-based fertilizers come in different forms, including monoammonium phosphate, diammonium phosphate, and triple superphosphate, and are utilized to bolster root growth and enhance crop resilience to stress.

- Potassium-Based Fertilizers: Potassium is vital for overall plant health and plays a part in water regulation, stress tolerance, and disease resistance. Potassium-based fertilizers come in various forms, including potassium chloride, potassium sulfate, and potassium nitrate, and are used to enhance crop quality and yield, particularly in crops such as fruits, vegetables, and cereals.

Related Equipments-

In the fertilizer industry, a variety of equipment is utilized, including:

- Granulators – These machines transform fertilizer powders into granules.

- Dryers – They are utilized to eliminate moisture content from fertilizer granules or powders.

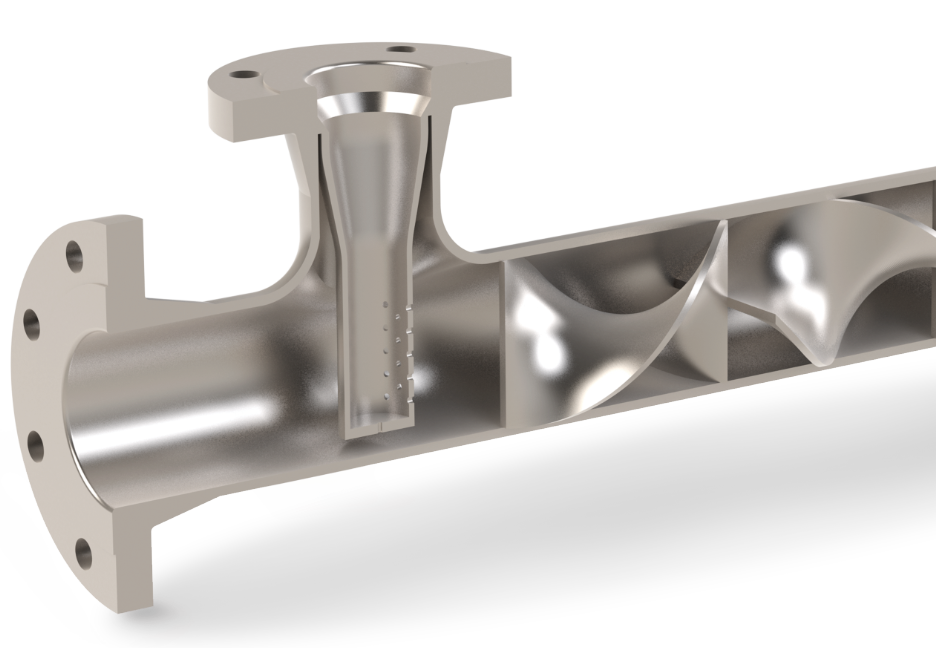

- Mixers – They are employed to combine ingredients and produce a range of fertilizer blends.

- Crushers – Raw materials such as phosphates, potash, and other minerals are reduced in size through the use of crushers.

- Conveyors – They are utilized to transfer fertilizer materials from one place to another.

- Screeners – Screeners separate fertilizer particles into various sizes for improved processing and handling.

- Bagging machines – They are used to package fertilizer into bags of various sizes for easy handling and transportation.

- Palletizing machines – These machines arrange bags of fertilizer into pallets for more efficient handling and transportation.

- Storage silos – They are utilized to store fertilizer prior to and after processing.

- Blenders – They are utilized to mix different fertilizer types to produce specific blends for diverse crops and soil types.