ABOUT-

In recent years, the surfactant industry in India has been steadily growing, primarily due to the rising demand for personal care products, home care products, and industrial applications. Surfactants are chemical compounds that can reduce the surface tension of a liquid, making it easier to spread, and they find use in numerous industries, including detergents, textiles, and food.

Research and Markets reported that in 2020, the Indian surfactant market was valued at USD 3.76 billion, and it is projected to reach USD 5.27 billion by 2026, with a compound annual growth rate (CAGR) of 5.6% during the forecast period. The report highlighted that the market growth is primarily driven by the increasing demand for personal care products, rising urbanization, and a growing population.

The largest application segment of the surfactant market in India is the home care segment, which includes dishwashing and laundry detergents. Additionally, the personal care segment, which encompasses products such as shampoos, soaps, and shower gels, is also a significant driver of the market.

ASSOCIATION-

| NAME | URL |

| European Committee of Organic Surfactants and their Intermediates | https://www.cesio.eu/ |

| The Indian Home & Personal Care Industry Association | http://www.ihpcia.org/ |

DESCRIPTION-

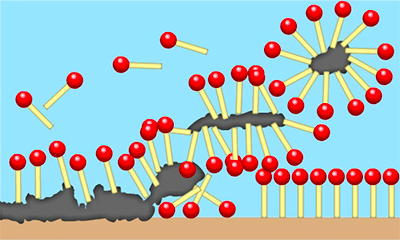

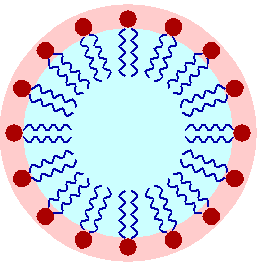

Surfactants, also known as surface active agents, are chemical compounds with a distinctive structure that finds broad applications in both industrial and household products. Their unique structure enables them to lower the surface tension of liquids, making it easier to dissolve oils, dirt, and other substances that are usually hard to remove with water alone.

There are four main categories of surfactants based on their ionic charge:

- Anionic surfactants: This type of surfactant has a head group with a negative charge and is frequently employed in household cleaning products such as laundry detergents, dish soaps, and all-purpose cleaners.

- Cationic surfactants: This type of surfactant has a head group with a positive charge and is used in fabric softeners, hair conditioners, and some disinfectants.

- Nonionic surfactants: This type of surfactant has no charge and is commonly used in personal care items such as shampoos, body washes, and toothpaste.

- Amphoteric surfactants: This type of surfactant has a head group with both positive and negative charges and is used in a variety of applications, including personal care products and cleaning products.

RELATED EQUIPMENTS:

The production of surfactants in the industry involves the use of various industrial equipment to produce different types of surfactants. Some of the commonly used equipment in surfactant production are:

- Reactors: These are large vessels used for synthesizing surfactants by reacting raw materials in the presence of a catalyst. Reactors are designed to provide agitation to promote mixing and control the reaction temperature.

- Distillation Columns: These are used for the separation and purification of surfactant products. Distillation columns are utilized to remove impurities and separate different surfactant components based on their boiling points.

- Mixing Tanks: These are used to blend surfactant products with other additives, such as fragrances and dyes, to create finished products such as soaps and detergents.

- Dryers: These are used to remove moisture from wet surfactant products, producing a dry product that can be stored or packaged. Spray dryers are commonly used in the surfactant industry.

- Filtration Equipment: This equipment is used to remove impurities from surfactant products. The most commonly used filters in the surfactant industry are pressure filters and vacuum filters.

- Pumps: Pumps are used for the transfer of surfactant products from one stage of the production process to another. Various types of pumps such as centrifugal pumps, diaphragm pumps, and peristaltic pumps are used in the industry.

- Heat Exchangers: These are used to regulate the temperature of the surfactant product during the manufacturing process.