ABOUT-

In recent years, the polymer industry has experienced rapid growth and is projected to maintain its upward trajectory in the future. These versatile materials, also known as plastics, are utilized in a diverse range of applications such as packaging materials, automotive components, and others, with demand for these products expected to rise in the foreseeable future. Polymer is one of the broadly used chemical merchandise in almost all the sectors this type of medical, aerospace, packaging, automotive, construction, electrical appliances, and clinical quarter, and consequently, the global polymers marketplace is prospering. Polymers are used extensively as an alternative of steel and mineral based merchandise due to its high overall performance, price-effectiveness, and low weight. Boom within the retail zone and prospering e-trade industry is worrying for more packaging material this is influencing the significance of the polymers marketplace.

Emerging markets, especially those in Asia, are a significant driving force behind the polymer industry’s growth. As these economies continue to expand and advance, the demand for polymer-based products is expected to escalate. Moreover, the demand for sustainable and environmentally friendly polymers is on the rise, as consumers and governments become more aware of the environmental impact of traditional plastics. In 2020, the global polymer market was worth approximately USD 556 billion and is predicted to increase to USD 810 billion by 2028, registering a CAGR of 5.1% during the forecast period. Various industries, such as packaging, automotive, construction, and electronics, drive the demand for polymers.

ASSOCIATION-

| NAME | URL |

| AIPMA | https://www.aipma.net/ |

| Asian Polymer Association | https://asianpolymer.org/index.html |

DESCRIPTION-

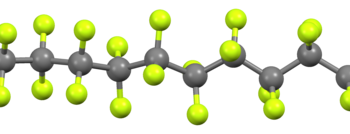

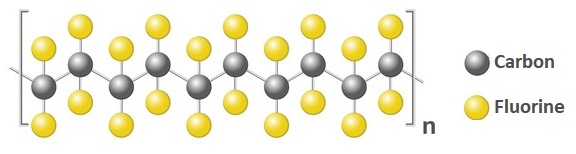

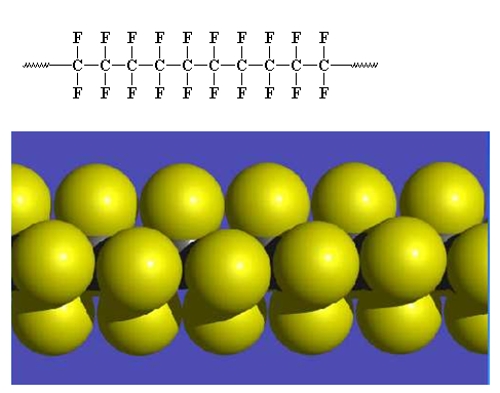

Polymers are complex molecules made up of many smaller subunits called monomers that are linked together chemically in long chains. The size of these chains can vary from a few to millions of monomers. Polymers can be made from various types of monomers, both natural and synthetic, and the properties of a polymer can be adjusted by selecting specific types of monomers and adjusting the way they are bonded.

Polymers are prized for their exceptional properties such as strength, flexibility, and lightness, and are therefore used in a diverse range of applications. They can be found in everyday items like plastic bags, bottles, toys, and clothing, as well as in more advanced fields such as medical implants, aerospace components, and electronics. Ongoing research and development continue to expand the potential uses of polymers while refining their properties.

Polymers come in various types based on their composition, structure, and properties. Some of the most common types include:

- Thermoplastics: These polymers retain their properties even after multiple melting and reshaping. Polyethylene, polypropylene, and polystyrene are some examples of thermoplastics.

- Thermosets: These polymers undergo a chemical reaction during processing, which results in a permanent cross-linking of the polymer chains, making them rigid and infusible. Epoxy resins, phenolic resins, and polyurethanes are some examples of thermosets.

- Elastomers: These are polymers that can be stretched and returned to their original shape. Natural rubber and synthetic rubbers like neoprene and silicone are some examples of elastomers.

- Biopolymers: These polymers are derived from natural sources like starch, cellulose, and proteins. They are eco-friendly and biodegradable, making them suitable for applications like biodegradable plastics and biopolymers used in medical settings.

- Conductive Polymers: These are polymers that can conduct electricity. They are useful in electronic devices, batteries, sensors, and more.

- Liquid Crystalline Polymers: These polymers have an ordered structure that resembles liquid crystals. They possess unique mechanical and electrical properties that make them suitable for use in displays and electronic devices.

- Composite Polymers: These are polymers made by combining two or more different types of polymers or other materials. Composites can have superior properties like being stronger or more durable than the individual materials.

RELATED EQUIPMENTS-

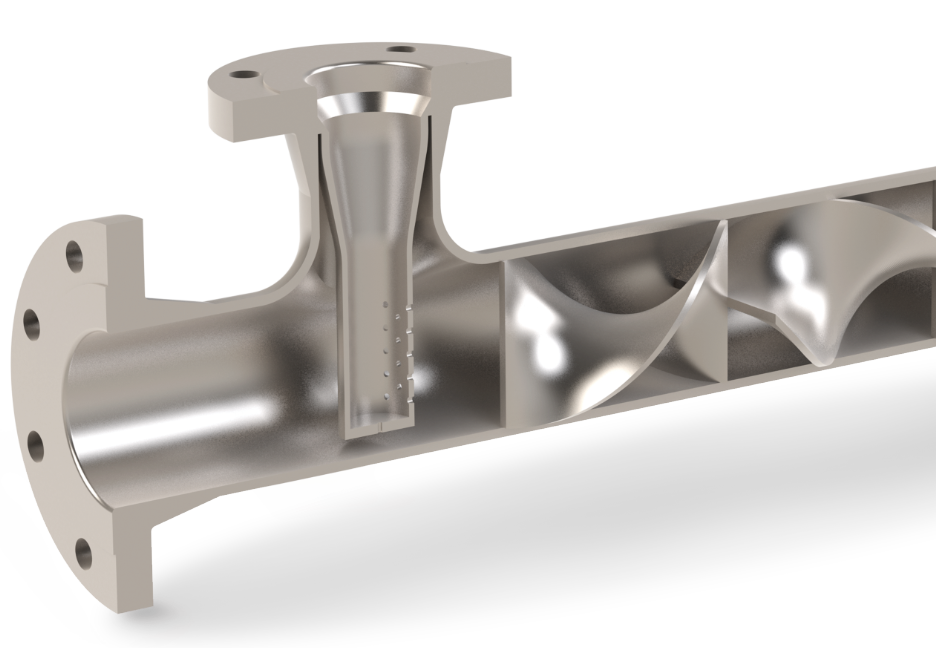

The polymer industry employs a range of equipment for polymer production, processing, and analysis. Below are some of the commonly used equipment in the polymer industry:

- Reactors: These are vessels where chemical reactions occur to synthesize polymer chains.

- Extruders: These machines melt and shape polymer pellets into different forms such as tubes, films, fibers, and sheets.

- Injection molding machines: These machines use high pressure to inject melted polymer into a mold to form products such as toys, bottle caps, and medical devices.

- Blow molding machines: These machines blow air into heated plastic tubes to expand them into desired shapes such as bottles, containers, and automotive parts.

- Mixing equipment: This includes mixers, blenders, and kneaders that mix polymers with additives, pigments, and fillers to improve the properties of the final product.

- Testing equipment: This includes various instruments used to measure properties such as tensile strength, viscosity, molecular weight, and thermal stability of polymers.

- Analytical equipment: This includes chromatography and spectrophotometry instruments used to determine the chemical composition of polymers.

- Cooling equipment: This includes chillers and cooling towers that lower the temperature of equipment and polymer products during processing.

- Filtration equipment: This includes filters and strainers that remove impurities and contaminants from polymer products.